Overview of CNC Machines

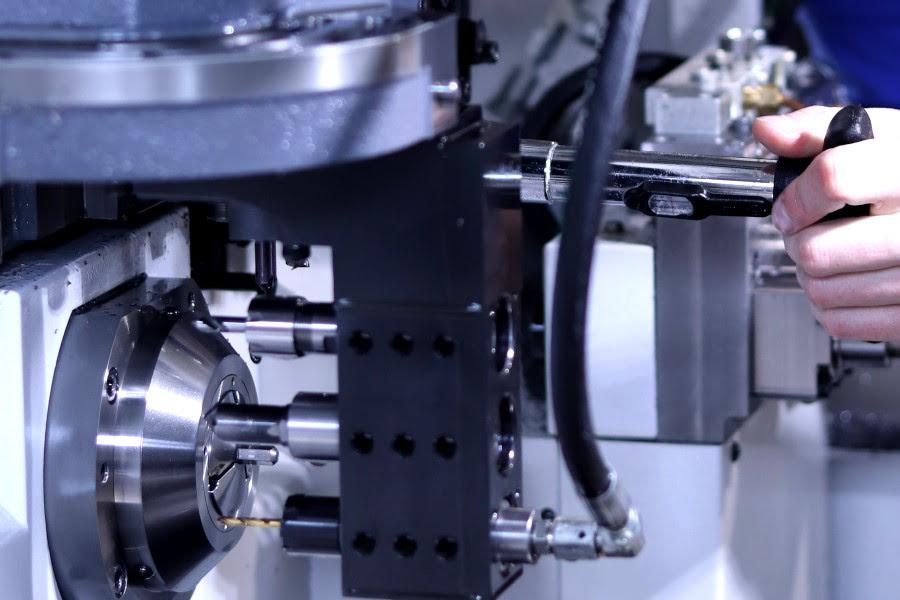

Computer Numerical Control (CNC) machines play a pivotal role in today’s manufacturing industry, particularly in China. They are known for their accuracy, efficiency, and cost-effectiveness. A CNC machining manufacturer manipulates pre-programmed software to control factory machinery and tools.

The advent of CNC machines has brought significant improvements to the manufacturing industry, particularly in tasks involving cutting, curving, and milling. Chinese manufacturers have adopted CNC machines, enabling increased productivity and consistency.

Types of CNC Machines Used by Chinese CNC Machining Manufacturers

- CNC Milling Machines

CNC Milling Machines are popular amongst Chinese CNC machining manufacturers due to their ability to create intricate parts through the drilling and cutting of solid materials. Popular models include XYZ Proturn SLX 425 and Haas Mini Mill 2.

- CNC Turning Machines

As a cnc machining manufacturer, these rotary cutting tools can produce cylindrical parts swiftly and accurately. The EMCO E-350 and the Okuma – Genos L300 are among the industry favorites.

- CNC Grinding Machines

CNC grinding machines are used to shape the outside of an object through grinding. Preferred models include the Supertec Machinery Inc. Cylindrical Grinder and the Kellenberger 10.

- CNC Laser Cutting Machines

Laser cutting machines, well-liked by the cnc machining manufacturer, use a high-energy light beam to cut through materials with unparalleled precision. The TruLaser Cell 8031 and the Bodor P3015 are popular choices.

- CNC Plasma Cutting Machines

The use of a plasma torch to cut materials makes these machines ideal for CNC machining manufacturers interested in handling metals. The Powermax45 XP and the VersaCut 60 are some top picks.

CNC Electric Discharge Machines (EDM)

CNC EDM machines shape hard materials that are electrically conductive. Some prominent models include the Mitsubishi MV1200-S and the Makino Edge3.

After understanding the different types of machines used by a CNC machining manufacturer, the next step is comparing machines to determine which would be best for your specific needs.

Importance and variety of CNC Machines

The variety of CNC machines allows CNC machining manufacturers to find machines that fulfill their specific needs. These machines are also adaptable, versatile, and can be updated to meet the ever-changing demands of the manufacturing industry.

Looking ahead, data indicates that CNC machines will continue to be vital in the Chinese Manufacturing Industry. A study shows that China’s investment in smart manufacturing, including CNC machines, is expected to exceed $300 billion by 2030.

In conclusion, whether it is a CNC Milling Machine, a CNC Turning Machine, or a CNC Grinding Machine, each one plays an integral role in the success of a CNC machining manufacturer in China. It’s vital to select the right CNC machine based on your distinct manufacturing needs, the overall budget, and the materials you plan to work with.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

Common Types of CNC Machines Used by the Manufacturers

- CNC Milling Machines

- Used for drilling and cutting solid materials.

- Models: XYZ Proturn SLX 425, Haas Mini Mill 2.

- CNC Turning Machines

- Rotary cutting for cylindrical parts.

- Models: EMCO E-350, Okuma Genos L300.

- CNC Grinding Machines

- Shapes objects through grinding.

- Models: Supertec Cylindrical Grinder, Kellenberger 10.

- CNC Laser Cutting Machines

- Cuts with a laser beam.

- Models: TruLaser Cell 8031, Bodor P3015.

- CNC Plasma Cutting Machines

- Uses a plasma torch for cutting metals.

- Models: Powermax45 XP, VersaCut 60.

- CNC Electric Discharge Machines (EDM)

- Shapes electrically conductive materials.

- Models: Mitsubishi MV1200-S, Makino Edge3.

The Journey of an American Purchasing Manager

In the bustling city of New York, a renowned Purchasing Manager, Bob, carried a tremendous responsibility on his shoulders. He was tasked with the daunting duty of procuring faucets, showerheads, and drinking fountains from efficient and reliable CNC machining manufacturers in Asia.

Once Bob identified his potential partners, he embarked on his journey to China, the hub of manufacturing, with a primary focus on sourcing from a CNC machining manufacturer.

Discovering the world of CNC Machining Manufacturers

In China, Bob was fascinated by the array of manufacturing techniques used by the various CNC machining manufacturers. His aim was to find an ideal partner who could provide high precision products, using the most sophisticated machinery.

Bob visited several factories, each one specializing in different categories of CNC machining manufacturing. From multi-tasking machines to turning centers, milling centers to Swiss-style lathes, Bob began to understand why China had become the manufacturing powerhouse of the world.

Finding the right CNC Machining Manufacturer

After extensive research, Bob finally narrowed down his choices to a CNC machining manufacturer who specialized in faucets, showerheads, and drinking fountains. This CNC machining manufacturer utilized a variety of machines such as a 5-axis machining, advanced CNC milling, and CNC turning machines.

Impressed by the precision and efficiency, Bob felt confident that he was on the right track. The quality produced by this CNC machining manufacturer convinced him that he made the right decision.

Overcoming Challenges

Despite the exciting prospects, Bob faced some challenges in dealing with a Chinese CNC machining manufacturer. There were communication barriers, cultural differences, and differences in business ethics, but Bob’s determination kept him going.

With a clear understanding of his procurement objectives and armed with necessary research, he successfully overcome these hurdles with his chosen CNC machining manufacturer. Instead of seeing them as obstacles, he viewed them as unique aspects of the sourcing journey, giving him insight into a new world.

Success Awaits

With the successful dealing and strategic alliance with the CNC machining manufacturer, Bob returned to America, thrilled about the new opportunities and advancements that awaited his company. His decision to source from a Chinese CNC machining manufacturer by investing time and effort in understanding their approach to precision engineering and manufacturing techniques resulted in a profitable partnership.

This venture not only enhanced his company’s manufacturing capabilities but also highlighted the immense benefits and potentials when carefully sourcing from a CNC machining manufacturer in China.

This story of Bob’s journey reveals why Chinese CNC machining manufacturers have become a popular choice for many, thanks to their diverse and highly efficient machining capabilities. Bob’s procurement success story serves as a beacon, guiding others in their sourcing endeavors from a CNC machining manufacturer.

Reference

1. What Is CNC Machining? An Overview of the CNC Machining Process

2. A Brief Introduction to CNC MACHINING

3. Different Types of CNC Machines and Their Applications