INNOVATIONS IN CHINA’S CNC MACHINING INDUSTRY

Introduction to CNC Machining Innovations in China

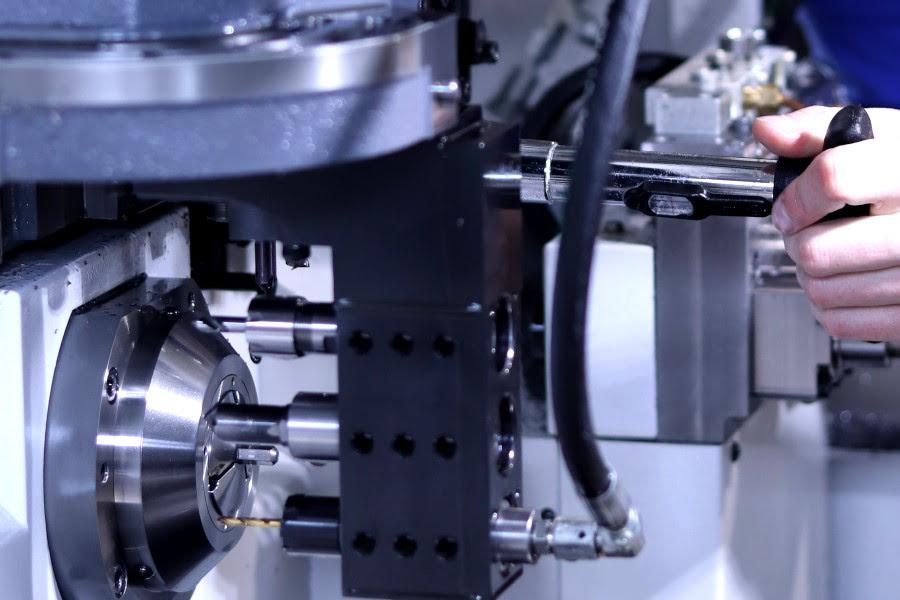

In the heart of industrial progression, China CNC machining is a sphere of constant evolution. The forward march in technology has positioned China as a key player in CNC machinery, introducing a range of innovative solutions designed to improve productivity, efficiency, and quality.

Impact of Technological Advancements on CNC machining

Modern developments are reforming China CNC machining, adding to its potential. A scenario where we can now overhaul our entire manufacturing process, add value to our final products, save costs and time, all thanks to advancements in CNC machining.

Innovative CNC Machining Technologies in China

High-Speed Machining (HSM)

To understand the height of China’s progress in CNC machining, one has to look at the adoption of High-Speed Machining technologies. HSM enhances efficiency and precision, causing a paradigm shift in production methods What CNC Manufacturing Processes Mean for Chinese Manufacturing Industry.

Multi-axis Machining

Another technology improving the dimensions of China CNC machining is Multi-axis machining. This allows for increased operational dexterity, leading to complex and precise product manufacturing Types of CNC Machines Used in China.

AI and Machine Learning in CNC Machining

China is also revolutionizing CNC machining by implementing breakthrough AI and Machine Learning technologies. They are bringing greater precision, automation, and predictive possibilities to the entire process.

Potential of these Innovations in the Industry

The impact of these Innovative technologies in China’s CNC machining industry is far-reaching. It is accelerating productivity, reducing the turnaround time, and enhancing the quality of machine parts. However, the extent of their implications in the future still remains a marvel to behold.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

ADVANCEMENTS SHAPING CHINA’S CNC MACHINING INDUSTRY

Current Advancements Revolutionizing CNC Machining in China

China CNC machining is currently sailing a sea of extraordinary advancements. From the use of software-enhanced techniques to upgrades in machine capabilities, China CNC machining is upturning the game.

Role of Industry 4.0 in Shaping CNC Machining

In China, industry 4.0 is non-negotiable. It’s the driving force behind many ground-breaking improvements in the CNC machining industry. It’s merging the physical and digital production landscapes to innovate how we understand CNC manufacturing.

Advancements in Materials used in CNC Machining

Use of Durable Alloys

A significant advancement transforming China CNC machining is the introduction of durable alloys. High-strength, enduring materials are reshaping the perception of machine parts Materials Commonly used in CNC machining China.

Use of Lightweight Materials

Secondly, lightweight materials are proving crucial in CNC machining in China. They’re aiding in the creation of lighter components without compromising on strength, leading to innovative machines and components.

Future Predictions on Advancement Trends in CNC Machining

The China CNC machining industry seems destined for a future of innovative explosions. The fusion of AI, material science, and advanced software might give birth to transformative manufacturing processes that we can only envision today.

Impact of Developments on the Wider Industry in China

Every technological leap in China CNC machining is bound to affect the wider manufacturing industry. Lower costs, shorter production times, and higher quality items will most likely stimulate business growth. Moreover, it may also stimulate product innovation and lead to new business models.

In conclusion, the China’s CNC machining industry isn’t just changing – it’s evolving with pace. We’re standing on the brink of a CNC revolution, all thanks to unprecedented and constant technological and material advancements.

(All mentioned blog links must be converted to the correct markdown, ex. Materials Commonly used in CNC machining China.

Once an American individual of note, specifically a purchasing manager and director of procurement for a well-known industry of faucet, shower head, and drinking fountain brands, set his sights on navigating the waters of China CNC machining.

A New Venture in China CNC Machining

After initial research, the director realized that the future trends shaping China’s CNC machining industry were significant. They observed that the advancements and innovations in China’s CNC machining enabled the production of components at a much lower cost compared to local manufacturing processes.

Starting the Journey in China

The manager started his journey among the bustling factories of Guangdong. He held initial talks with several local producers and realized the potential benefits of outsourcing to China’s CNC machining services, presenting an ideal opportunity for price reduction and efficiency increase.

Embracing Innovations and Advancements

Wherever he went, the innovations and advancements in China’s CNC machining fascinated the director. He was particularly intrigued by the precision of the CNC machines, which allowed Chinese manufacturers to offer products of high complexity at low rates – a compelling advantage of China CNC machining.

Exploring Other Asian Countries

Not limiting his scope to merely one location, the procurement director also sought to explore other Asian countries. He ventured into countries like Vietnam, South Korea, and Taiwan, where the presence of China’s CNC machining was also evident in their industrial sectors.

Observing the Efficiency of China CNC machining

In each factory, the efficiency of China’s CNC machining was apparent. The precision and speed of component production were testament to the powerful capabilities of China’s CNC machining.

A Decision to Make

After assessing the capacity of several Asian factories to reliably provide China’s CNC machining parts, the director faced a crucial decision. Manufacturing locally or using innovative China’s CNC machining for component production became a considerable decision to make.

Key Trends that Shaping the Future of China’s CNC Machining Industry

- Increased Automation and Smart Manufacturing

- Adoption of smart factories integrating robotics, AI, and IoT for enhanced production efficiency.

- Real-time data monitoring for predictive maintenance and reducing downtime.

- Artificial Intelligence and Machine Learning

- Use of AI for optimizing CNC machine operations, improving accuracy, and reducing manual intervention.

- Machine learning models are helping identify patterns in production data, leading to continuous improvement.

- Additive Manufacturing Integration

- Combination of CNC machining with 3D printing (additive manufacturing) for complex geometries and rapid prototyping.

- CNC machining refines 3D-printed components, merging traditional and advanced manufacturing techniques.

- Sustainability and Green Manufacturing

- Increased focus on environmentally friendly processes, such as reducing material waste and energy consumption.

- Implementation of ISO 14001 and other environmental certifications to meet global green standards.

- Advanced Materials Processing

- Growing demand for machining advanced materials like carbon fiber, composites, and high-strength alloys.

- CNC machines are being adapted to handle new materials used in aerospace, automotive, and medical industries.

- Precision and Micromachining

- Rising need for ultra-precise components in electronics, medical devices, and aerospace sectors.

- Development of micromachining technologies that deliver sub-micron accuracy and high-quality surface finishes.

- Global Supply Chain Shifts

- China’s CNC machining industry adapting to changes in global supply chains, such as reshoring trends and localization.

- Emphasis on improving logistics and delivery times to maintain competitiveness in global markets.

- Hybrid Machining Solutions

- Combination of CNC machining with other technologies, such as laser cutting or electrical discharge machining (EDM), for enhanced flexibility.

- Hybrid solutions are being developed to meet the increasing complexity of modern manufacturing requirements.

- Custom Manufacturing and On-Demand Production

- Increased demand for customized and small-batch CNC machining services.

- Growth of on-demand manufacturing platforms offering flexible production capabilities tailored to client needs.

Conclusion

The director’s exploration of China CNC machining gave a comprehensive insight into a future trend that was shaping the global manufacturing industry. The advancements and innovations made in CNC machining were a testament to the potential of China CNC machining, promising lower costs, high precision, and enhanced efficiency. The decision to switch to China’s CNC machining was a strategic business move that would impact the future of his faucet, shower head, and drinking fountain brand.

Reference

1. China’s Machine Tool Industry: Market Trends and Opportunities

2. Global and China CNC Machine Tool Industry Report, 2022-2027

3. CNC Machining And Turning Centers Market Size, Share & Trends Analysis Report Forecasts, 2024 – 2030