Understanding Quotes for Chinese CNC Machining Manufacturers

Quotes serve as a pricing compass in the world of CNC machining manufacturers. The quote of a CNC machining manufacturer can determine a project’s feasibility and play a crucial role in budgeting.

Importance of Quotes for CNC Machining

For managers working on a stringent budget, CNC machining quotes can provide invaluable insight into the financial obligations of a project. Rationally, they will run feasibility checks based on the quote provided by a CNC machining manufacturer and decide on the viability of said project.

In my personal experience, a start-up product developer needed to produce custom parts but had a limited budget to work with. They approached several CNC machining manufacturers and collated their quotes, which formed the basis for an encompassing budget plan for the project life-cycle.

How Chinese CNC Machining Manufacturers Prepare Quotes

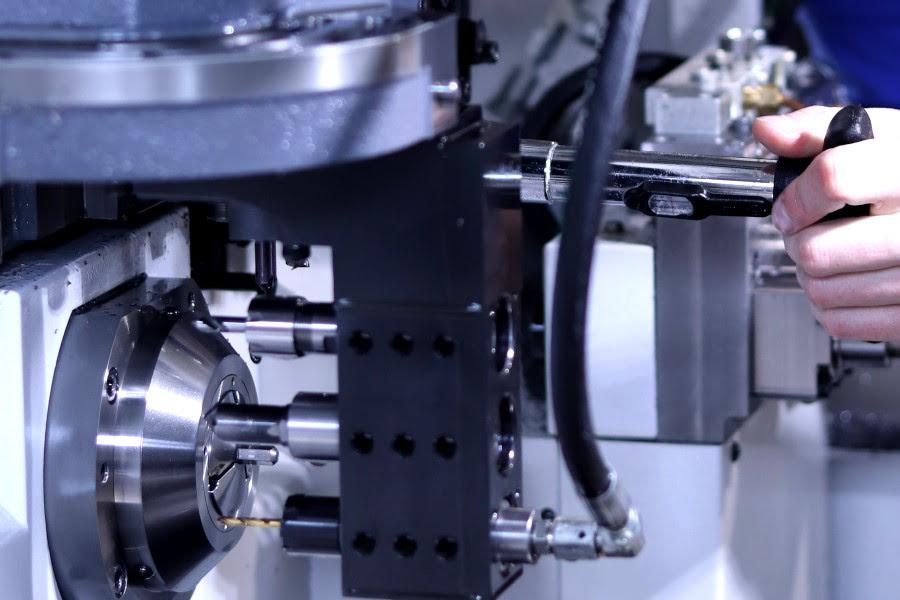

How exactly do Chinese CNC machining manufacturers prepare their quotes?

This question invariably probes into the countless variables influencing the quotes. Factors such as the complexity of work, lead times, customization level, and volume of order all play a huge part. To add to these is the type of material to be used, which is often influenced by current market prices and the ultimate function of the part being made. Including shipping costs and certification requirements source in our blog, the cost model can be quite complex.

Thankfully, a majority of Chinese CNC machining manufacturers operate on a common pricing model. By this, costs are divided into direct costs (materials, labor etc.,) and indirect costs (overheads, marketing etc.,). They mix all these costs with a fixed or variable margin to arrive at the quote.

Decoding a CNC Machining Quote

A good CNC machining quote should transparently cut the costs into clear categories – starting from material procurement to post-production operations like assembly, packaging, and shipping.

Comparing quotes from different CNC machining manufacturers can reveal considerable variants in costs. This task is simplified by a comprehensive analysis that would evaluate costs from all potential partners and provide a useful overall picture. It’s essential to ensure you’re comparing like-for-like, especially with regards to material grades, tolerance, and finishes. Here is a great guide to help you when choosing a Chinese CNC machining parts factory partner.

Understanding Pricing Structures for Chinese CNC Machining Manufacturers

Types of Pricing Structures

CNC machining manufacturers can have a range of pricing structures, and it’s important to understand how these can affect your costs. The three common pricing formats are fixed pricing, time and material pricing, and cost-plus pricing.

With fixed pricing, the quoted price remains the same regardless of the manufacturer’s costs. Time and material pricing means costs are calculated based on labor and material used. Cost-plus pricing is where costs are determined by the cost of production, plus a profit margin.

Factors Affecting Pricing Structures

What a manufacturer pays in overheads can influence pricing structures. CNC machining manufacturers must consider labor costs and material costs. As a rule of thumb, labor forces in China will command lower wages due to the cost of living compared to more economically developed countries.

Material costs are also important. Certain materials may be more expensive due to their quality, such as titanium, while others like aluminum, maybe cheaper.

Finally, manufacturers aim to make a profit on each project, with markup determining the percentage for profit.

Insights for Negotiating Pricing Structures

Through years of research, I’ve discovered that the best way to negotiate pricing structures is to first understand the fair market price. Look at what’s being offered by various CNC machining manufacturers, and find a common middle ground.

Take leverage in pricing benchmarks – it will provide substantial insights into what a fair price might look like. Further, you can apply strategies learned from our blog for negotiating with CNC machining service providers.

In sum, understanding how CNC machining manufacturers calculate their prices and effectively negotiating pricing structures can make a significant difference in the outcome of a project. Make sure you do your homework before initiating any meaningful business relationship.

Understanding the Journey of an American Purchasing Manager Sourcing in Asia

Meet John. He’s a purchasing manager for a globally recognized U.S. brand specializing in faucets, showerheads, and drinking fountains. His mission was to source these items from China and other Asian countries, specifically from the manufacturers.

Identifying Suitable CNC Machining Manufacturers

John began by making a comprehensive list of powerful Asian manufacturers. He focused primarily on China due to its advanced manufacturing capabilities. He faced numerous challenges along the way, but the first step was critical: finding the right manufacturers with competitive pricing structures and high-quality products.

Communicating Requirements to CNC Machining Manufacturers

Next, he contacted the selected CNC machining manufacturers to communicate his brand’s specific needs and requirements accurately. He ensured that these manufacturers understood his requirements and were capable of producing goods that adhered to strict American quality and safety standards.

Analyzing Quotes from CNC Machining Manufacturers

John spent countless hours analyzing and comparing quotes from different manufacturers. He found that each manufacturer had a diverse pricing structure, which made direct comparison tricky. He had to consider numerous elements, including material costs, labor fees, and export taxes.

Negotiating Rates with CNC Machining Manufacturers

He leveraged his excellent negotiation skills to discuss the price points with the manufacturers. His primary goal was to ensure that final products met quality standards while also making economic sense for his company. Therefore, successful negotiations were crucial.

Finalizing Orders with CNC Machining Manufacturers

After thorough vetting, John finally selected a few top manufacturers to manufacture his brand’s products. He discussed production timelines, shipment schedules, and payment terms in further detail before finalizing orders. His attention to detail was the key to successful sourcing.

Monitoring Quality Control with CNC Machining Manufacturers

Post-order, John maintained regular communication with the manufacturers to monitor production quality and adherence to agreed-upon timelines. He knew that his company’s reputation depended on the quality of the products that these manufacturers produced.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

Quotes and Pricing Structures for Chinese Manufacturers

- Importance of Quotes: Helps determine project feasibility and create a detailed budget plan.

- Quote Components: Includes direct (materials, labor) and indirect (overhead, marketing) costs, plus a profit margin.

- Common Pricing Structures:

- Fixed pricing (unchanging)

- Time and material pricing (based on work done)

- Cost-plus pricing (production cost + profit margin)

- Key Factors: Material type, labor costs, order volume, and market conditions influence the pricing structure.

Conclusion

In conclusion, John’s story is a practical guide for any purchasing manager looking to procure goods from CNC machining manufacturers in China or other Asian countries. By effectively understanding and navigating pricing structures, anyone can source high-quality products at competitive rates, thus ensuring success in their ventures.

Reference

1. What is CNC? Terminology, history and applicable materials

2. China’s Industrial Machinery Market: Insights & Opportunities

3. What is CNC Machining: Definition, Process, Purpose & More