Understanding CNC Machining

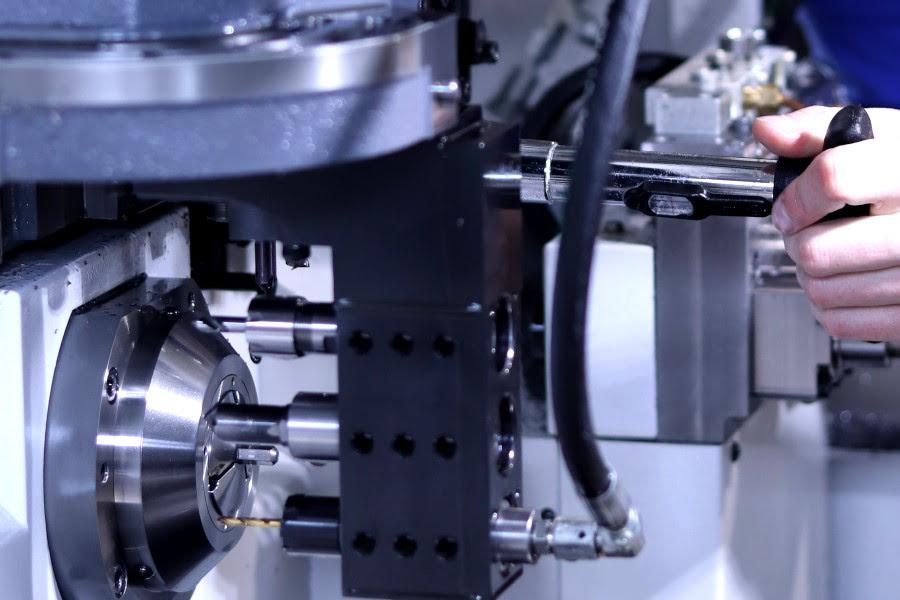

CNC or Computer Numerical Control machining is a manufacturing process that uses pre-programmed computer software to dictate movement of factory machinery and tools. In China’s manufacturing industry, CNC machining plays a crucial role.

From nimble start-ups to established industrial giants, businesses across the spectrum are reaping the benefits of this innovative technique. Particularly in China’s manufacturing industry, CNC machining has taken center stage, powering production lines and accelerating growth. It’s time to take a deep dive into understanding CNC Machining – revolutionize your manufacturing process today with unparalleled efficiency and accuracy.

Discover how this game-changing technology can elevate your operations to a global standard. From precision production to sustainable practices, reap the rewards of a technology that’s shaping the future of manufacturing. Stay ahead of the competition with CNC machining – the smart choice for the modern manufacturer.

What is CNC Machining: Processes and Applications

Essentially, CNC machining operates through numerical control, where a software program is specifically created for an object, and the machines are programmed to create it. The entire process, from prototyping to production, utilizes specialized software to instruct the machining tools.

This advanced manufacturing method operates through numerical control, a process where a custom software program is designed for each unique object. These programs guide the machinery from initial prototyping through to full-scale production. The cutting-edge machines are programmed meticulously to fabricate the object with utmost precision. The entire operation relies on specialized software, which directs the machining tools in a strategic, efficient manner.

Are you curious about the various types of CNC machines in use today? Read more about the types of CNC machines used in China. Venture into the realm of innovation with us. We promise, it’s a journey worth embarking on.

China’s CNC Machining Industry

China’s CNC machining industry has a strong capacity for delivering a variety of materials. These range from metals such as aluminum and brass to various plastics and fiberglass types – the choice depends on the purpose and the specific production requirements of the end product.

The choice of material is meticulously matched to the exact purpose and production requirements of the end product, underscoring the industry’s commitment to quality and precision. Check out our full guide about the materials commonly used in Chinese CNC Machining.

Whether you’re in the automotive, electronics, aerospace sector or any industry requiring precision parts, China’s CNC machining capabilities can meet your demands. With an excellent blend of skill, technology, and diverse material options, expect nothing but excellence in quality and precision.

Top CNC Machining Hubs and their Capabilities

China’s major CNC machining hubs are located in Shenzhen and Guangzhou. They are home to a vast number of factories equipped with state-of-the-art machinery. This makes them capable of handling a wide variety of requests and large order volumes. What makes them stand out is their ability to seamlessly blend technology and skill to deliver top-notch CNC machining results. You can read our comprehensive overview of China’s CNC machining capabilities here. Equip yourself with the knowledge to make informed choices in your next CNC machining venture.

Moreover, these operational hubs guarantee efficient communication and proper supervision which ensures a smooth and timely completion of projects. In addition, the blend of affordability and quality offered is unmatched; thereby, making these cities an optimal choice for your CNC machining needs.

Sourcing CNC Machining Services in China

Chinese CNC service capabilities are competitive globally due to their comprehensive suite of offerings, quality, and adaptability to market trends. Their adaptability and commitment to providing top-notch services make them a go-to destination for CNC needs worldwide. Explore this article on comparing Chinese CNC services to global providers for an in-depth review. Dive deep into the world of CNC machining services in China, and understand why many are opting for these services.

Furthermore, it’s their unique blend of technology expertise and customer-centric approach that sets Chinese CNC services apart. With competitive pricing, swift delivery, and a focus on innovation, these services have successfully created a niche for themselves in the international market. Their seamless integration with various industrial needs and ongoing evolution in tune with the latest trends only cement their place as a premier destination for all things CNC.

Future Trends in China’s CNC Machining Industry

Technology and customer demands constantly shape industry trends. Companies are increasingly adopting Industry 4.0 norms, and Chinese CNC machining factories are no exception. Chinese CNC factories are leading the charge in embracing these advancements. They are playing a critical role in contributing to this technological revolution. To harness the power of these emerging trends, stay updated with these future trends, which will define the next phase of China’s CNC machining industry. Embrace the future today by understanding the active future trends defining and driving the growth of the CNC machining industry in China.

By understanding these active future trends, you will be paving your way towards a technologically advanced future. Embrace these advancements today, and gear yourself towards significant growth in the CNC machining industry within China. Witness a revolution in making, be a part of the change today!

Quality Control and Standards

Chinese CNC factories prioritize customer satisfaction and hence ensure that their services meet international quality standards. They have certifications and follow stringent quality control measures. They make certain that the products dispatched from the manufacturing unit stand as examples of world-class quality. These factories have keen eyes for detail, making sure every part of a product is perfectly crafted and error-free. Learn about quality assurance in Chinese CNC machining services. Here, you will get a glimpse of what to expect and how to ensure quality when dealing with these state-of-art factories. Let’s partner in creating products that don’t just meet but exceed expectations.

This resource will provide you with an in-depth understanding of what to anticipate and how to verify quality when you engage with these advanced manufacturing units. Let’s forge a partnership that is dedicated to delivering more than just products, but exceptional experiences and satisfaction.

Dealing with Chinese CNC Machining Manufacturers

Knowing how to negotiate contracts, devise effective communication strategies and manage time zone differences are crucial when dealing with Chinese CNC suppliers. It’s not just about finding the right manufacturer, but also efficiently managing the interaction. The negotiation process is a key aspect that needs your attention, making it crucial to learn how to effectively negotiate contracts. Furthermore, bridging the communication gap is equally important. A solid foundation in innovative communication strategies will ensure smooth business transactions with Chinese CNC suppliers. Equip yourself with these essential skills to get the most out of your partnerships with Chinese CNC manufacturers.

The process of negotiation is a crucial part where your attention is highly needed. It’s not a battle, but a chance to build a fruitful partnership. Apart from this, bridging the communication gap is a necessity – it requires strategies that are as innovative as they are effective. Equip yourself with these crucial skills and you’ll find your dealings with Chinese CNC manufacturers not only smoother but also significantly more rewarding.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

Shipping and Customs

Once you’ve received an ideal quotation, signed a profitable contract and are assured of the quality of production, the last leg of the CNC sourcing journey revolves around shipping and customs. This is the final, yet pivotal part of your CNC sourcing journey that demands utmost attention. Mismanagement can lead to delays, additional costs, or even losses. This guide will walk you through these steps.

The guide has covered everything you need to know to get your CNC parts from Chinese machining factories to your doorstep hassle-free. This guide promises to enlighten you on every aspect, ensuring a smooth transition from production to delivery. Discover the tricks of the trade and perfect your sourcing journey with this enlightening guide, offering insights from production to delivery.

Cost optimizations

Cost plays a significant role in sourcing decisions. Understanding the factors affecting CNC Machining costs will help you optimize and yield maximum value from the investment. By delving deeper into these elements, you can optimize your investments, driving not only cost efficiencies but also enhancing the overall value of your investment. So, take the leap and equip yourself with the right knowledge to yield maximum benefits from your investments. It’s all about cost optimizations.

So, why wait? Arm yourself with the knowledge necessary to reap maximum benefits from your investments. Remember, it’s not just about cutting costs, it’s about optimizing them smarter and better. Join us on this journey of knowledge and let’s drive cost efficiencies together!

Informative Snapshot of CNC Machining Services in China

| Topic | Details |

| CNC Machining Overview | CNC (Computer Numerical Control) machining uses software to control machinery for precision manufacturing, enhancing efficiency and accuracy. |

| China’s CNC Industry | China offers a vast array of materials, including metals and plastics, with advanced machining hubs in Shenzhen and Guangzhou. |

| Capabilities | Factories in China excel in precision parts for industries like automotive, aerospace, and electronics. |

| Cost Optimization | Factors such as material, complexity, and volume affect costs, with China offering competitive pricing. |

| Quality Control | CNC factories in China adhere to international standards, ensuring high quality and precision in production. |

| Future Trends | Integration of Industry 4.0 and automation are shaping the future of CNC machining in China. |

Conclusion

China’s CNC Machining industry continues to evolve with technological advancements and changing global trends. By understanding the resources available and how best to navigate the landscape, businesses can benefit immensely from the capabilities on offer. This knowledge will enable you to partner with the ideal factory that suits your needs. Tapping into the potential of this industry doesn’t just mean surviving, but thriving in an environment of ceaseless innovation. Capitalize on your newfound comprehension to identify and partner with the factory that perfectly aligns with your business requirements. Equipped with this knowledge, you are not just navigating the terrain, but mastering it, setting a course for exponential growth and success.

Explore the potentials of this innovative industry and don’t just survive – thrive! With us, you won’t just be learning to navigate the terrain, you’ll be mastering it. Prepare to set a course for exponential growth and success with our expert advice. Partner with us and tap into the power of ceaseless innovation and growth in the CNC machining industry.