Understanding Shipping for CNC parts from Chinese Machining Factories

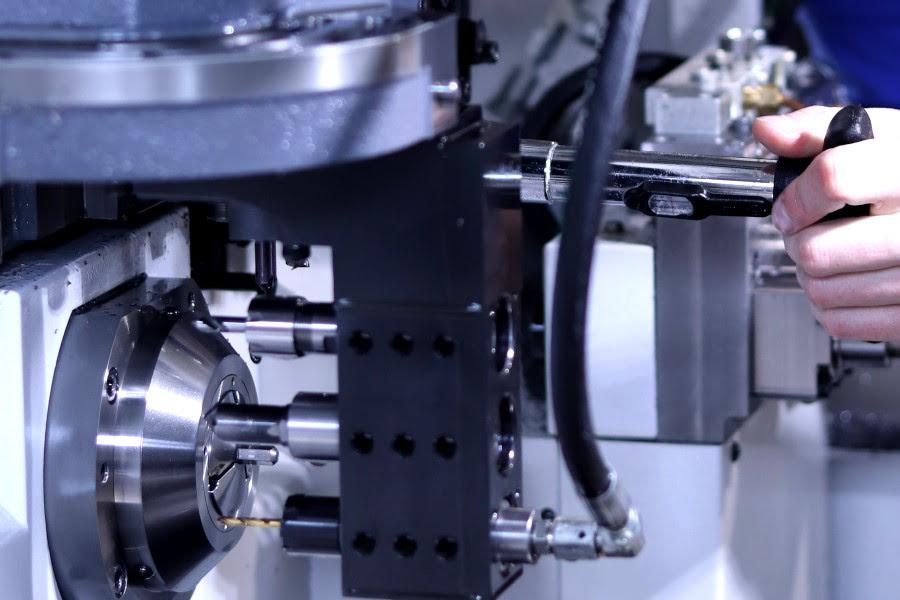

Introduction to Chinese Machining Factories

China, with its CNC machining factory history dating back to the dawn of globalization, anchored itself as a crucial node in the global supply chain. Today a CNC machining factory in China contributes significantly to the world’s production of CNC machine parts. China’s CNC machining coverage spans from aerospace components to household appliances. The variety of parts produced by CNC machining factories in China is testament to their importance in global CNC manufacturing.

Comprehensive Guide to Shipping CNC Parts

Shipping CNC parts require a blend of knowledge, experience, and meticulousness. Beyond choosing the right shipping method—air, sea, or rail, the intricacies of these machining factory shipping involve working with freight forwarders, understanding proper packaging and labeling, managing costs, and dealing with potential disruptions.

Take heed to your machine parts choice of shipping method. Air freight often serves urgent orders, although its high price leads many to opt for sea or rail freight. I remember sourcing a CNC machine parts for a client. An unexpected rush order came in, and we had no choice but to ship by air. Unexpected shipping costs could heavily impact the overall price. Therefore, it’s vital to be clear about shipping preferences when negotiating contracts with a CNC machining factory in China.

Freight forwarders act as middlemen between the factory and you. They handle logistics, ensuring your CNC parts reach their destination safely and promptly. Furthermore, each CNC machining factory follows specific packaging and labeling requirements. Misunderstandings could lead to shipment rejection or delays, increasing costs.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

Navigating Customs for CNC Parts Imported from China

Understanding Chinese Export Regulations

Chinese export regulations can be complex. Before goods leave a CNC machining factory, we require proper documentation. Some of these documents include commercial invoices and packing lists – seemingly basic but of paramount importance. It’s essential to familiarize yourself with the rules. Once a CNC machining factory I worked with overlooked some minor amendments in the export duties. Consequently, we lost valuable time and money on penalties.

From export duties and taxes to export control regulations, every CNC machining factory in China must comply with these directives. For example, certain CNC parts might require special licenses before exporting. As a buyer, knowing these aspects when dealing with a factory in China helps prevent unpleasant surprises.

Guide to Import Regulations in Destination Country

Import regulations in the destination country are equally important. Similar to exports, imports require documentation and there are duties to pay. Import control regulations ensure goods entering the country meet the set standards.

Mitigating Customs Challenges

Customs challenges can cause delays and inflate costs. However, understanding them and planning for uncertainties when dealing with a factory can help mitigate these challenges. Customs brokers, adept at navigating customs procedures, can be invaluable. They hash out customs complexities while you focus on your core business areas.

With a CNC machining factory, maintaining a comprehensive record of all transactions can be helpful. In case of discrepancies or disputes, these records serve as your go-to resource for resolution. Keeping tabs on past transactions with your CNC machining factory also aids in future dealings, shaping places of improvement and effective modes of operation.

CNC machining factories in China have seen remarkable growth, catapulting China into the zenith of global CNC manufacturing. Yet, understanding shipping and customs procedures can be confusing and challenging. However, with diligence, knowledge, and the right partnerships, these challenges can be tackled, paving the way for efficient and profitable dealings with any CNC machining factory in China.

An American Director of Procurement and the Quest for Quality

In his search to forge a lucrative, cost-effective partnership, John Smith, Director of Procurement for a leading US faucet, shower head, and drinking fountain brands, decided it was time to source from Asia, specifically from the CNC Machining Factory in China.

Embarking on the Journey

John immediately understood that the potential from aligning with a CNC machining factory could be transformative to the company. He was excited, yet apprehensive, knowing that misunderstandings or miscommunications could lead to costly errors.

Tapping into a CNC Machining Factory

Hong Guan, a supplier from a reputable factory in China, was John’s first point of contact. They discussed product specifications, orders, and prices. It was crucial to ensure each machining factory met their high standards.

The Inspection

By partnering with a factory, sourcing across the globe became efficient and cost-effective. John decided to undertake a factory inspection, an essential yet often overlooked step, to verify the manufacturing capabilities of the factory in question.

Customs and Shipping

One critical aspect of the process was getting CNC parts through customs. With parts sourced from a machine factory, it was important to understand that customs could be a complex beast to navigate and any delay could significantly impact production timelines.

Shipping and Customs Guide

- Shipping Methods: Options include air freight (for urgent orders), sea freight (cost-effective for bulk), and rail freight.

- Freight Forwarders: They manage logistics between the factory and the buyer.

- Customs Documentation: Key documents include commercial invoices and packing lists.

- Export Regulations: Factories must comply with Chinese export duties and taxes.

- Customs Brokers: They help navigate customs procedures in destination countries.

- Challenges: Delays and costs can arise if regulations aren’t followed properly

Conclusion

John’s story offers key insights into how working with a CNC machining factory can lead to unprecedented growth opportunities and cost savings. It underscores the importance of due diligence, precise communication, and understanding customs and shipping procedures when partnering with a CNC machining factory.

Reference

1. What is CNC Machining: Definition, Process, Purpose & More

2. What Is CNC Machining? The Complete Basics to Get Started

3. How to Import from China: Best Practices