Understanding CNC Machining

Definition of CNC Machining

It all begins with CNC Machining, a technique used to manipulate tools with computer numerical control (CNC).

Brief History of CNC Machining

The roots of CNC Machining can be traced back to the mid-20th century, with the first numeric control machine devised in 1949 by John T. Parsons and Frank L. Stulen.

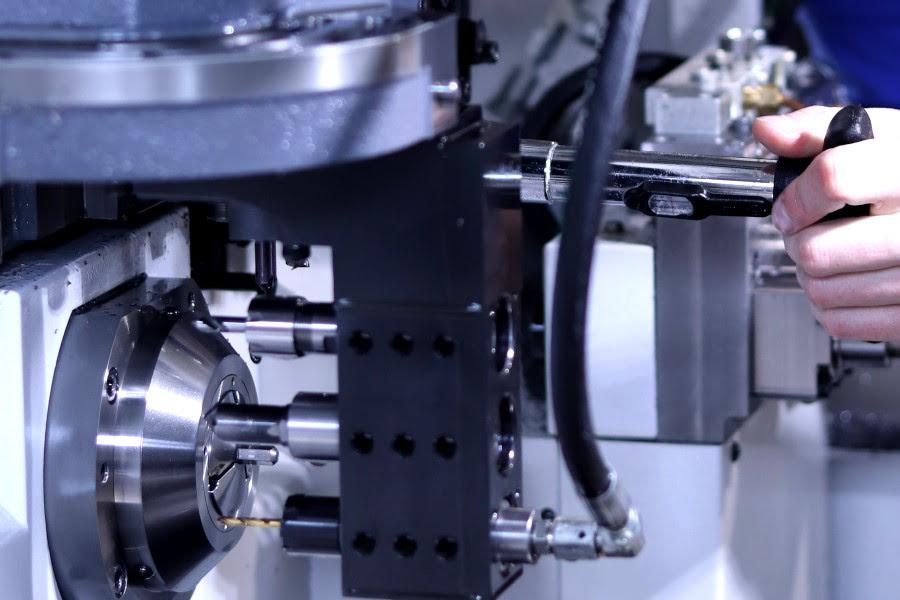

Key Components and Functionality of CNC Machines

A typical CNC machine comprises key components like a controller, drive system, spindle, and tool assembly services. These components function interactively, controlled by a dedicated computer program.

Different Types of CNC Machines

Impressively, CNC technology is incorporated in a diverse range of machines, such as milling machines, lathe machines, laser cutters, and more. We covered different types of machines widely used by Chinese CNC Machining manufacturers in one of our blog posts.

CNC Machining Processes – An Overview

CNC Machining process includes various techniques like:

- Drilling – This common process in CNC Machining uses a rotating cutting tool to remove material and create holes.

- Milling – Milling involves rotation of cutting tools to remove material from the workpiece. Different types of mills like flat, ball end and chamfer mills are used based on the desired design.

- Turning – In this process, a single-point cutting tool removes material from the workpiece’s surface while it spins on a rotating axis.

- Grinding – Grinding CNC machines reduces the workpiece to the desired size and surface finish.

- Cutting -This method involves transforming a raw workpiece into a finished product by removing excess material.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

CNC Machining in China’s Manufacturing Industry

State of CNC Machining in China: Past and Present

It has transformed China’s manufacturing industry in the past few decades. The growth, mostly technology-driven, demonstrates China’s constant strive for innovation.

Role of CNC Machining in China’s Manufacturing Sector

It significantly boosts China’s manufacturing sector by offering precise, efficient, and bulk production capabilities.

Key Applications of CNC Machining in Different Chinese Industries

CNC Machining services are deployed across various industries in China:

- Automotive

The precision and speed of CNC Machining facilitate the easy and efficient production of vehicle parts.

- Aerospace

The need for high precision and accordance with strict standards in the aerospace industry highly relies on CNC Machining processes.

- Electronics

The miniaturization trend in the electronics industry heavily rests on CNC Machining for creating small, intricate components.

- Healthcare

CNC Machining helps manufacture medical devices with utmost precision and hygiene, enabling China to be a leading global supplier.

Benefits of CNC Machining to China’s Manufacturing Industry

CNC Machining brings about enhanced accuracy, productivity, versatility, and cost savings to the Chinese manufacturing industry.

Future Trends: Emerging Technologies Influencing CNC Machining in China’s Manufacturing

The future of CN Machining in China is expected to incorporate AI, IoT, and 3D printing technologies, reshaping the manufacturing landscape.

Challenges Facing CNC Machining in China’s Manufacturing Industry and Possible Solutions

While this process has immensely benefited China’s manufacturing industry, there remain challenges such as skilled labor shortage and transparency issues. One solution might be adopting advanced training and implementing transparency remedies.

Preventive Measures to Ensure Quality

| Preventive Measure | Description |

| Routine Machine Maintenance and Checks | Regular machine inspections to ensure optimal working conditions. |

| Proper Calibration of CNC Machines | Frequent calibration to maintain dimensional accuracy. |

| Staff Training on Accurate Machine Operation | Training staff to promptly address machine errors and malfunctions. |

| Implementing Advanced Software Applications | Using cutting-edge software to enhance precision and minimize defects. |

| AI and IoT Integration in CNC Machines | Leveraging AI and IoT for smarter, more efficient operations. |

| Leveraging Robotics | Utilizing robotics to handle labor-intensive tasks with more precision and consistency. |

| Material Waste Reduction and Sustainability | Recycling and optimizing processes to minimize material waste. |

| 3D Printing for Pre-Production Evaluation | Using 3D printing to detect errors early, preventing waste and defects in final products. |

Journey of an American Purchasing Manager

Once upon a time in the heartland of America, John Doe, a seasoned purchasing manager, was working for a leading faucet, shower head, and drinking fountain brand. He was given the challenging task of sourcing these products from China and other Asian countries. The primary process that he was planning to leverage was this machining.

CNC Machining and Its Role

John was well aware that CNC machining was a core part of China’s manufacturing industry. He knew that Chinese manufacturers, utilizing this process, could produce intricate parts with fine details that would be impossible to achieve with manual machining.

The advantage was clear – manufacturers could produce high-quality, precise parts, consistently and quickly. This would allow John’s company to offer a wide range of premium products at competitive prices.

Search for the Perfect Manufacturer

John started his search by identifying potential manufacturers that had a strong track record using CNC machining. He used various sourcing platforms to narrow down his search, focusing on manufacturers who had positive reviews for their machining capabilities.

He was looking for a manufacturer that could guarantee precision, quick turnaround, and cost-effectiveness. John knew that it would help maintain consistent quality while meeting the high demand for their products.

The First Contact and Negotiation

After selecting a few potential manufacturers, John initiated contact. He communicated his specific requirements, emphasizing the importance of the quality achieved through this process.

During negotiations, John repeatedly emphasized the importance of CNC in producing high-quality faucets, shower heads, and drinking fountains. He wanted a partner that not only understood the detailed process but also had the capabilities to bring their designs to life accurately.

Visiting the Manufacturer’s Floor in China

Eventually, John selected a manufacturer that met his criteria and traveled to China to visit the manufacturer’s facility. He was eager to see the CNC equipment and observe the manufacturing process firsthand.

On the factory floor, he witnessed the entire process: from the programming of the machine, the selection and loading of the tools, to the cutting of the materials. John was impressed by the efficiency and precision of the process.

Successful Partnership – Love at First Cut

After witnessing the manufacturer’s capabilities, John was confident that he had made the correct choice. The manufacturer not only demonstrated a deep understanding of CNC but also showed a commitment to maintaining high quality in all production phases.

Conclusion

After months of collaboration, the first products were manufactured and shipped to America. The parts were immaculately crafted, thanks to the accuracy of this machining. The success of the new product line solidified John’s belief in the power of this in China’s manufacturing industry.

In conclusion, the essence of this tale of John’s journey illustrates the power and potential of CNC machining in sourcing high-quality products from China.

Reference

2. Definition and history of CNC Machining

3. Common Used CNC Terms and Definitions

4. The Growth History of CNC Machining in China

5. CNC Machining Services in China: Outsourcing, Considerations & Advantages

Master Your Global Supply Chain: The Ultimate Asia Sourcing Checklist