Understanding CNC Machining Parts Factory in China

China is a global leader in manufacturing, and their CNC machining parts factory sector is a staple of that dominance. The country’s aptitude for producing high-quality, cost-efficient pieces has positioned it as an attractive option for many businesses.

Introduction to CNC Machining in China

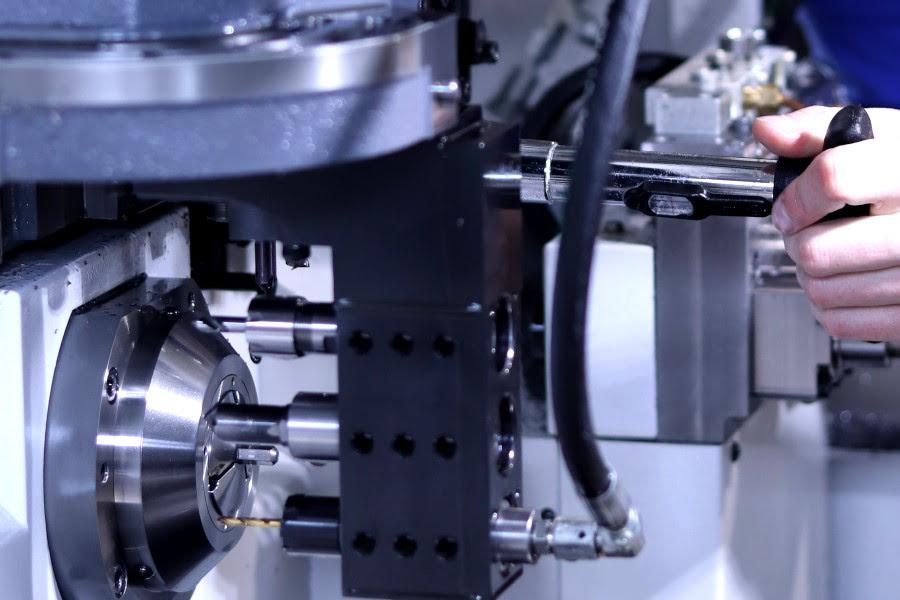

The story of China’s embrace of CNC machining reflects its pursuit of progress. This method, which uses pre-programmed software to control machinery, has revolutionized the manufacturing industry by offering precision and speed that manual operation cannot match. The elements of CNC processing are intricate, but in essence, it coordinates the movement of factory tools and machinery, crafting the detailed components that are the lifeblood of many products.

Market Overview of CNC Machining in China

The Chinese CNC machining market has displayed impressive growth over the years, fueled by the country’s industrial boom. Companies relying on CNC machining can expect this trend to continue, with the market projected to rise by over 6% by 2025. This continued expansion indicates a robust and dynamic sector, capable of keeping pace with a rapidly evolving global marketplace.

Key Factors to Consider When Choosing a Chinese CNC Machining Parts Factory Partner

- Quality Assurance and Standards

As is the case with any business relationship, trust is paramount. When considering a CNC machining parts factory, examine their quality assurance measures, and ensure they hold certifications such as ISO. These accolades underline a commitment to international standards as pointed out in this blog post. Also, assess their cleanliness protocols and inspection procedures which will help minimize the occurrence of quality issues as we discussed in another article.

- Technological Capabilities

Technology plays a critical role in CNC machining. As such, evaluate a factory’s technological prowess. Are they utilizing the latest CNC technology and equipment? Does their factory staff possess the required digital and technological proficiency?

- Factory Experience

An experienced CNC machining parts factory is more likely to deliver a level of service that meets your needs. Consider the number of years they’ve been in business, their past work, portfolio, and client testimonials which provide insights into the factory’s reliability and consistency.

- Cost and Financial Factors

Understanding a factory’s pricing model is also vital, as it offers insight into cost elements that could affect your bottom line. Additionally, evaluates the factory’s financial stability — a secure partner will be more capable of delivering consistent, quality performance.

- Production Capacity and Lead Time

Recognizing a factory’s production schedule and their capacity to meet deadlines is crucial to ensuring smooth operations. Delays can impact your own productivity, so partnering with a factory proficient at meeting timelines can avert potential supply chain disruptions.

- Communication and Service

Good communication can prevent costly errors or misunderstandings. Therefore, it’s crucial to consider how easy it is to communicate with the factory. Evaluate their dedication to customer service and satisfaction.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

First Encounter with a CNC Machining Parts Factory

John Hansen, an accomplished American purchasing manager and director of procurement for one of the leading faucet, shower head, and drinking fountain brands in the US, decided to source in China and other Asian countries. This was due to the superior quality and cost-effectiveness of the CNC machining parts factories in the region.

John first came across a Chinese CNC machining parts factory at a global trade expo. The factory’s presentation on their advanced CNC machining capabilities, resulting quality of products, and the broad range of customizable options they offered piqued his interest.

Why Choose a Chinese CNC Machining Parts Factory

Given the intense global competition, every American purchasing director acknowledges the need for quality and affordability that a Chinese CNC machining parts factory can provide. The technological sophistication, efficient operations, and lower labor and production costs make these factories an attractive option.

John’s Strategic Approach to Sourcing

John adopted a cautious approach in sourcing from a CNC machining parts factory. He wasn’t swayed solely by attractive pricing; instead, he looked for certifications, technology used, production capacity, and delivery times.

Evaluating a CNC Machining Parts Factory

He first evaluated the CNC machining capabilities of a prospective CNC machining parts factory by analyzing their current production, studying their recent innovations, and assessing their potential to meet his brand’s product demands.

Risk Assessment & Quality Assurance

Ensuring products met the quality standards required by his American clientele was John’s main concern. He thoroughly examined the risk management strategies and quality control protocols of each CNC machining parts factory to ensure his company’s reputation would not be compromised.

Assembly, Packaging, and Delivery

Lastly, he considered the assembly, packaging, and delivery processes of the CNC machining parts factory. This included reviewing delivery timelines, packaging quality, and aftersales service.

What to Consider When Choosing a Chinese CNC Machining Parts Factory Partner

| Factor | Description | Additional Considerations |

| Experience and Expertise | Evaluate the factory’s experience in CNC machining and the expertise of their team. | Check for certifications, years in business, and past projects. Look for specialization in your industry or specific machining techniques. |

| Quality Control | Review the factory’s quality control processes and standards. | Ensure they have ISO certifications and other relevant quality certifications. Inquire about their quality inspection procedures and defect rates. |

| Machinery and Technology | Assess the types and quality of machinery and technology used. | Verify if they use advanced and up-to-date CNC machines and technology. Consider if they invest in new technology and maintenance. |

| Production Capacity | Determine the factory’s ability to meet your production needs. | Check their capacity for large orders and their ability to scale production. Understand their lead times and flexibility. |

| Cost and Pricing | Analyze the cost structure and pricing model of the factory. | Compare pricing with other factories and ensure there are no hidden costs. Understand their pricing flexibility and any bulk order discounts. |

| Communication and Support | Evaluate the effectiveness of their communication and customer support. | Check if they provide clear and timely responses. Assess their ability to handle inquiries and issues efficiently. |

| Location and Logistics | Consider the factory’s location in relation to your business. | Factor in shipping costs, delivery times, and any potential logistical challenges. Assess if their location impacts overall costs or supply chain efficiency. |

| Reputation and Reviews | Research the factory’s reputation and read customer reviews. | Look for reviews from other clients and check for any complaints or negative feedback. Consider reaching out to references or previous clients. |

| Compliance and Certifications | Ensure the factory complies with relevant industry standards and regulations. | Verify any necessary certifications related to environmental standards, labor laws, and industry-specific regulations. |

Conclusion

Choosing the right CNC machining parts factory in China involves thorough research and assessment. Taking into account their technological capabilities, production capacity, quality controls, and delivery processes is critical. Like John, the American purchasing manager, businesses can also benefit from meticulous sourcing strategies. It aids in reaping the cost and quality benefits that a competent CNC machining parts factory offers, ensuring business success in the long run.

Reference

1. What is CNC Machining: Definition, Process, Purpose & More

2. What Is CNC Machining? An Overview Of The CNC Machining Process

3. How to Choose your CNC Machining Shop: Top Factors