Understanding Quality Control in CNC Machining Service in China

Explanation of CNC Machining Services

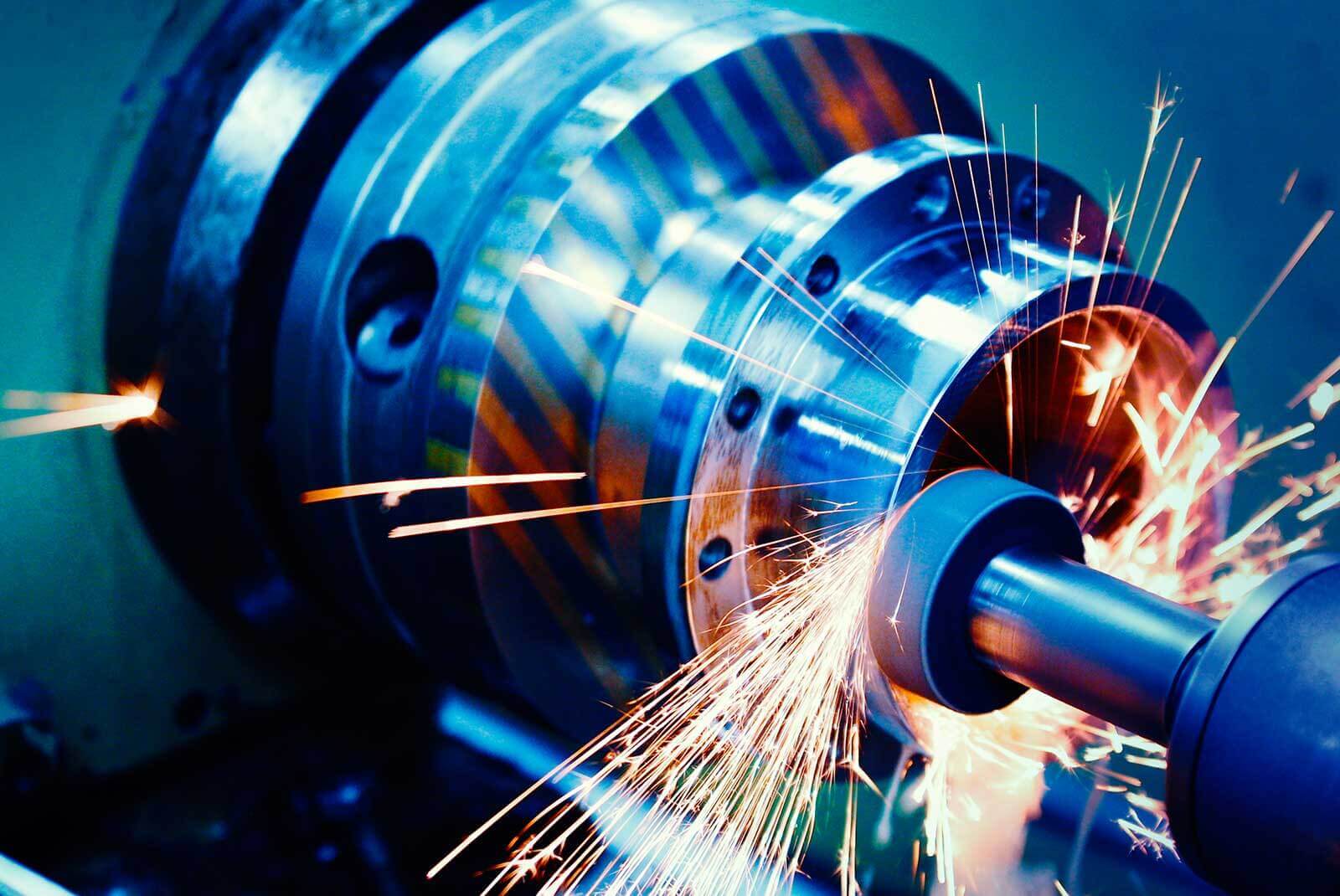

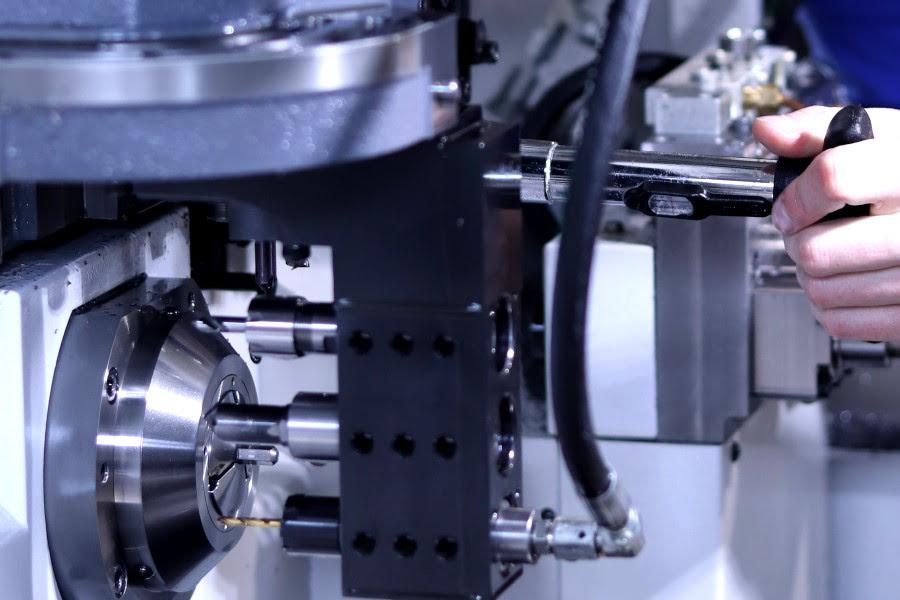

CNC machining is a process utilized in the manufacturing industry that involves the use of computers to control machine tools. Tools that are controlled in this manner vary depending on the type of CNC Machine and includes the lathe, mills, routers and grinders. CNC machining services China are essential in various industries like the automotive, aerospace, electronic, and medical industries due to their capacity to deliver precision parts in high volume at low costs.

Importance of Quality Control in CNC Machining Service

Quality control is the beating heart of any manufacturing process, inclusive of CNC machining services China. It guarantees product consistency and assures customers that the products are safe and reliable, meeting all necessary specifications. Unfortunately, the effects of poor quality control in CNC machining China may lead to product recalls, reject parts, and even loss of customers and reputation, making it crucial in the industry.

Overview of CNC Machining Service Providers in China

China has always been a hothouse for the development of CNC machining. The market is teeming with CNC machining services providers with proven track records. A wide array of providers ensures that local and international businesses have a rich market to choose from but also necessitate stringent measures to guarantee high-quality output.

Techniques for Implementing Effective Quality Control Measures with Chinese CNC Machining Service Providers

Building Strong Relationships with Providers

In CNC machining services China, a strong relationship with providers spices up the recipe for quality control. This implies open communication, transparency in operations, and a sharing of objectives. A strong relationship facilitates the exchange of ideas, leading to a better understanding of requirements, and hence, improved quality in CNC machining.

Regular Audits and Inspections

Audits and inspections are the tweezers in the world of CNC machining services China. They are necessary to guarantee that the quality of output is up to the required standards. Regular audits ensure that all quality control measures are in place and working effectively at all times. The benefits of committing to regular CNC machining audits trail from more reliable products to enhanced customer satisfaction.

Implementation of Quality Certification Standards

Quality certification standards such as ISO are akin to a gold stamp in CNC machining China. They certify that a provider has complied with all the necessary quality control measures. Their importance in enhancing quality control cannot be overstated as they validate a company’s commitment to quality and reliability.

Use of Advanced Technology for Quality Control

Modern technology and quality control in CNC machining have the perfect chemistry. Technologies, like CAD software and other inspection tools, have seen the light of CNC machining. Integrating such technologies can greatly improve precision, accuracy, and consequently, quality in CNC machining.

Case Studies

Learning from past mistakes is an art even in CNC machining China. There are numerous instances where quality control measures have been successful, and an examination of such instances may provide techniques on how to repeat such successes. Similarly, there are instances where the quality control measures failed and analyzing them can provide insights on what to avoid ensuring quality CNC machining.

To truly enact efficient CNC machining in China, one must embrace strategies and explore the world of CNC machining. From understanding the importance of CNC machining services China to building strong relationships with providers, regular audits, and inspections, implementation of quality certification standards, and the use of advanced technology for quality control. Rooting oneself in this wisdom will ensure successful delivery of high-quality CNC machining services.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

The Role of an American Purchasing Manager

Being an American purchasing manager means creating sourcing strategies. This is especially important when looking at options like CNC machining services in China. These managers often cover a wide range of products, from faucet brands to shower heads.

The Journey to CNC Machining Services China

One such manager, let’s call him John, found himself tasked with sourcing products in Asian countries. He faced often frustrating moments but eventually saw he had not just improved his company’s bottom line but also leveraged CNC machining services China to maintain quality.

Vicissitudes of Sourcing Journey

John quickly realized working with CNC machining services China could be challenging. Focused on quality control measures, he worked diligently to find trustworthy partners that met his company’s quality standards.

Building Trust with CNC Machining Services China

John conducted thorough due diligence, touring factories and meeting with potential partners. Building trust with CNC machining services China was critical to ensure quality.

Implementing Quality Control with CNC Machining Services China

Once the right partners were found, it was time to implement quality control measures. This required constant communication and supervision. To meet his rigorous quality standards, regular audits of CNC machining services were also conducted.

The Role of Quality Control Measures

Without effective quality control measures, sourcing from CNC machining services China could damage the brand. Yet, with proper guidelines in place and stringent audits, John managed to maintain the integrity of his products.

Case Study: Sourcing a Shower Head Brand from CNC Machining Services China

John’s sourcing campaign for a shower head brand stands as an outstanding case. He used CNC machining services China to get the products manufactured while adhering to stringent quality measures.

The Journey from Blueprint to Shower Head

John entrusted the blueprint to his chosen CNC machining services China. Through constant monitoring and scrutiny, the final product delivered was on par with John’s expectations.

Top Quality Control Measures for CNC Machining Service Providers

| Quality Control Measure | Description | Additional Considerations |

| Initial Supplier Evaluation | Thoroughly assess the CNC machining provider’s qualifications and past performance. | Review certifications (ISO 9001, ISO 14001, etc.), manufacturing capabilities, and past client feedback. Conduct on-site audits if possible. |

| Material Inspection | Ensure raw materials meet specified requirements before production. | Verify material certifications and conduct spot checks for consistency in material quality. Reject any materials that do not meet the standards. |

| In-Process Quality Checks | Conduct inspections during different stages of the machining process. | Use real-time quality monitoring with measurement tools like CMM (Coordinate Measuring Machine) to catch defects early and reduce rework. |

| Final Product Inspection | Perform a thorough check on the finished product before shipping. | Measure key dimensions, surface finish, and tolerances. Use visual inspections, along with precision instruments like calipers and micrometers. |

| Use of Advanced Measurement Tools | Utilize precise measurement tools to ensure dimensional accuracy. | CNC machining providers should use advanced tools such as CMM, laser scanners, and optical comparators to verify tolerances and product consistency. |

| Documentation and Reporting | Maintain detailed reports of inspections, test results, and corrective actions. | Ensure that quality reports and compliance documents are available for review. This helps track performance and address any quality issues efficiently. |

| Training of Personnel | Regularly train staff on quality control processes and standards. | Ensure that employees are up-to-date on the latest quality standards, measurement tools, and defect identification techniques. |

| Continuous Improvement Programs | Implement programs focused on continuous improvement of quality processes. | Encourage feedback loops from quality control teams and adopt Lean or Six Sigma methodologies to reduce waste and defects over time. |

| Supplier Collaboration | Maintain open communication and collaboration with CNC providers. | Work closely with CNC suppliers to address quality concerns, share feedback, and implement corrective actions to improve production quality. Regular reviews are essential. |

Final Thoughts on CNC Machining Services China

John’s journey highlights the efficacy of implementing effective quality control measures with CNC machining services China. It is a testament to how quality, cost-effectiveness, and efficiency can be achieved simultaneously.

Persistence and Vigilance

Persistence and vigilance are critical when dealing with CNC machining services in China. By keeping these two traits in mind along with effective quality control strategies, purchasing managers can successfully source in this part of the world.

Reference

1. Quality Control Services in China

2. Sustainable CNC Machining Operations

3. Quality Assurance in Manufacturing: Everything You Need to Know

4. A Deep Dive Into CNC Machining Quality Control and Inspection

5. CNC Machining Quality Testing and Inspection: Equipment, Types & Stages