Understanding Quality Assurance in Chinese CNC Machining Services

Definition of Quality Assurance (QA) in CNC

Quality Assurance (QA) is a system of processes and checks designed to ensure a specific level of quality in products. In the context of CNC machining, QA is crucial to delivering high precision parts that perform as expected. This becomes even more significant in China CNC Machining service, where quality consistency poses a significant challenge.

Importance of QA in Chinese CNC Machining

Every product that results from a China CNC Machining service, whether it’s a single component or a complex assembly, should uphold a stringent standard of excellence. Without the backbone of disciplined quality assurance, even the most promising design may fail in practical use due to overlooked defects.

Do you remember when I shared the story of a Chinese CNC machining factory which failed to implement a proper QA system? The factory had to halt production and suffered immense financial losses due to the massive recall of defective products. That’s why QA is not just about the final product; it is also about the reputation and customer satisfaction.

Key Elements of Quality Assurance in China CNC Machining

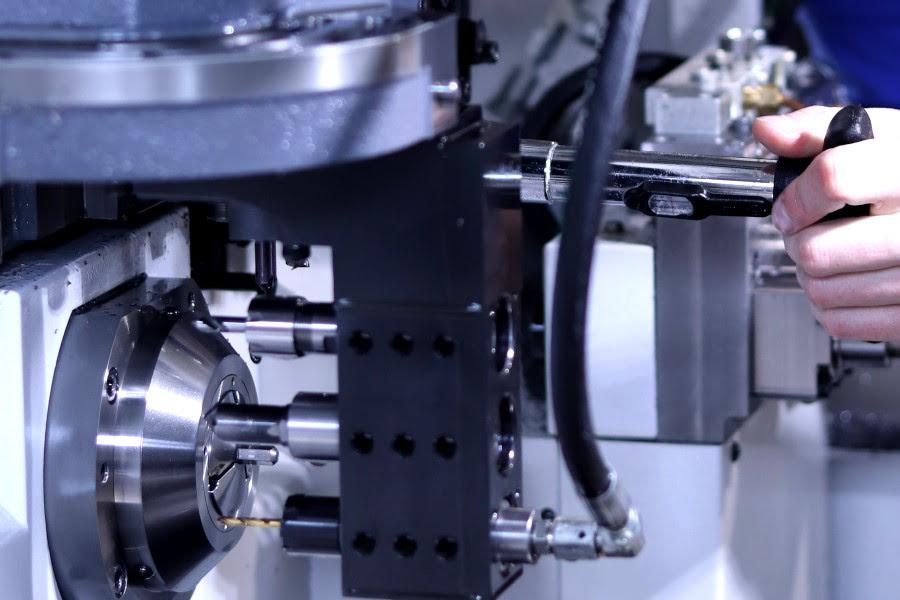

There are three key elements to ensuring quality in CNC machining services in China: inspection, calibration, and communication. Inspection of the final product is obviously crucial. It’s equally important, though, to make sure machines are calibrated correctly.

Regarding communication, it’s important that clear instructions, expectations, and standards are relayed effectively. Ineffective communication, as mentioned in this article, can lead to misunderstandings that result in quality issues.

Challenges in Assuring Quality in the Chinese CNC Machining Industry

While the need for quality assurance in China CNC Machining service is clear, several challenges may hinder its implementation and maintenance. Variations in local manufacturing practices, language barriers, time zone differences, and cultural nuances can all create hurdles.

Steps to Ensure Quality Assurance in CNC Machining Services in China

Careful Selection of CNC Machining Service Provider

A CNC machining service provider in China can make or break the quality of your products. As such, careful selection is paramount. One would need to consider criteria like experience, expertise, technology used, and more. Verifying the reputation of your China CNC Machining service provider can save you a lot of headaches. For more considerations, check out this helpful guide.

Regular Inspection and Quality Checks

Quality assurance in CNC machining services in China goes beyond just choosing the right provider. It’s important to conduct regular inspections and quality checks. This allows fast identification and correction of issues before they escalate. Technology is a great ally in this pursuit. Advanced testing methods and inspection equipment can help ensure high-quality output.

Establishing Strong Communication Channels with Service Providers

Effective communication is key when dealing with any China CNC Machining service provider. Clear and regular communication helps manage expectations, identify errors early, and foster a culture of continuous improvement.

Training Internal Teams for Quality Surveillance

The role of internal teams in quality assurance cannot be understated. Whether they’re conducting inspections or communicating with service providers, their competency is key for ensuring quality in a CNC Machining service. That’s why investing in training internal teams can bring huge returns.

Leverage International Standards for Quality Assurance

Lastly, leveraging international standards, no matter which China CNC Machining service provider you’re working with, is a universal language of quality assurance. This would include standards like ISO 9001. These standards ensure that no matter the operation’s location, there’s a harmonized approach to quality assurance. For a comprehensive understanding, you might want to give this read a go.

Just to reiterate, the success of any machining service project significantly depends on a robust quality assurance strategy. Regular inspections, responsive communication, and leveraging international standards are just as important as selecting the right service provider. With these measures in place, anyone can successfully navigate the Chinese CNC machining industry and attain the desired quality for their products.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

Key Quality Assurance Processes

| Process | Description |

| Inspection | Regular and thorough inspections to detect and rectify defects early on. |

| Calibration | Ensuring machines are calibrated to maintain precision and consistency. |

| Communication | Clear communication between the client and manufacturer to prevent errors. |

| International Standards (ISO) | Compliance with standards like ISO 9001 to ensure global quality benchmarks. |

| Sample Testing | Testing samples before full production to verify material and workmanship. |

John’s Experience with China CNC Machining Service

John Doe, an esteemed Purchasing Manager at a leading American sanitary ware company, had the significant responsibility of sourcing high-quality products from different parts of the globe. He recently discovered the potential of the China CNC machining service for faucets, shower heads, and drinking fountains.

John recognized the value and capability of this machining service in producing superior quality, precision parts. Therefore, he decided to take advantage of these services for his company’s needs.

Sourcing Sanitary Fittings from China

John launched an expedition to China and other Asian countries. His primary goal was finding a reputable China CNC machining service for his company’s products. He sought partners who could craft exquisite faucets, shower heads, and drinking fountains with impeccable durability and functionality.

Why China?

It didn’t take long for John to discover the superiority of the China CNC machining service. He found that these services combine both traditional and advanced machining techniques.

The Top Chinese CNC Machining Services

John curated a list of top China CNC machining service providers. Each company was assessed based on their technical capabilities, customer service, and quality assurance systems.

Ensuring Quality in Chinese CNC Machining Services

John’s primary concern was ensuring product quality. To reassure himself of the reliability of the China CNC machining service, he set up extensive tests and meticulous inspections on the received samples.

- Regular Product Testing

John encouraged regular testing of products produced by the China CNC machining service. He believed this testing was critical to ensuring consistent quality.

- Samples Inspection

Each China CNC machining service that John worked with was required to send samples for inspection. These samples underwent stringent tests to guarantee they met required standards.

Enhancing Relations with China CNC Machining Services

John put in efforts to cultivate sound relationships with his China CNC service providers. He believed that fostering good relationships would positively influence service delivery.

- Building Trust

His proactive approach to building trust among the China CNC machining service providers played a significant part in assuring quality CNC service.

- Open Communication

John encouraged open communication with the CNC machining service providers. He understood that clear communication was crucial in ensuring his expectations were met.

In conclusion, John found that sourcing quality faucets, shower heads and drinking fountains from China CNC machining service was a feasible and rewarding venture.

Reference

1. CNC Machining Services in China: Your Ultimate Guide

2. How to Choose the Best CNC Machining Services in China?

3. Top 10 CNC Machining Companies in China

4. Steps Involved In Quality Control And Inspection Of CNC Machining