Chinese CNC Machining Parts Factories – Unraveling the Puzzle

In digging into the roots of today’s manufacturing genius, you’d be led straight into the heart of China, to the birthplace of Computer Numerical Control (CNC) technology. The story of the Chinese CNC machining parts factory began humbly in the mid-20th century, soon revolutionizing the manufacturing industry worldwide.

The leap from manual to automated control in the machining process was a significant milestone; it opened doors of endless possibilities. CNC machining reimagined the global manufacturing industry, and China led the brigade – a testament to its resilience and innovation.

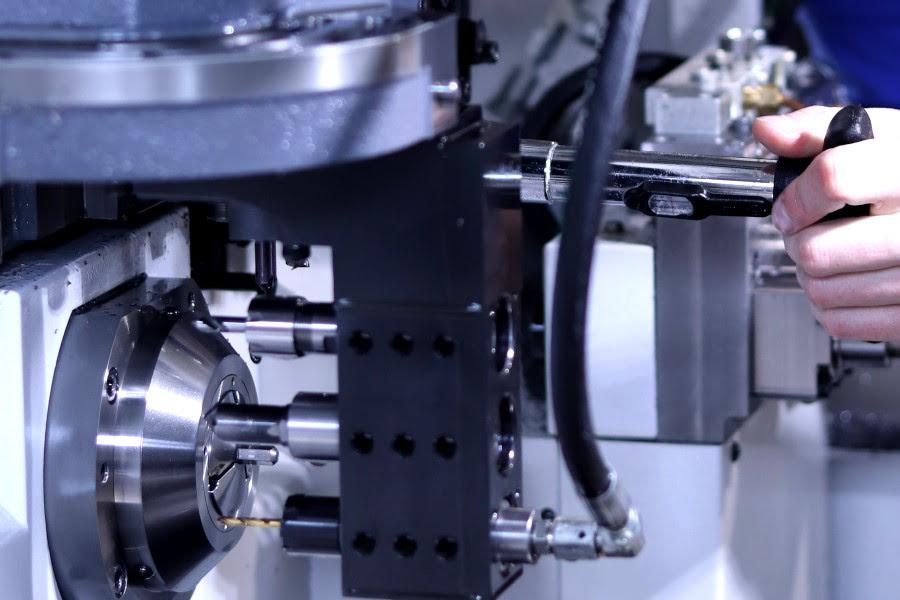

CNC machines tirelessly carve, grind, cut, and shape materials, transforming metal blocks into the most intricate parts used in various industries. Today, CNC machining in China read more about this fascinating journey that is the nucleus of global manufacturing, and rightfully so!

The Materials’ Symphony in a Chinese CNC Machining Parts Factory

Walk into any Chinese CNC machining parts factory, and you’ll witness a symphony of materials working in harmony. Metals take the lead, mainly with four stars: Aluminum, Brass, Steel, Titanium. Each has unique properties lending themselves to varied applications learn more about these metal types.

Not restricted to metals, CNC machining reaches out to a wide spectrum of materials, a testament to its flexibility. Plastics such as ABS, Nylon, Polycarbonate, and Polyvinyl Chloride (PVC) are key players too, offering versatility and cost-effectiveness.

Composite materials, an amalgamation of various materials, are like the orchestra’s conductor, combining strengths and compensating weaknesses for an optimized performance.

Selecting the right material in a CNC machining parts factory is far from arbitrary. It is a thoughtful decision driven by factors like product application, durability, and manufacturing cost. For example, while Aluminum might be a go-to for lightweight yet sturdy parts, ABS plastic could be preferable for more cost-effective components.

The careful choice of materials has a significant impact on the final product’s quality and functionality. A rightly chosen material can make or break a product, thereby making it a critical decision in a CNC machining parts factory. Therefore, partnering with a Chinese factory that understands and respects these parameters is crucial to explore partnership selection criteria.

In the grand scheme of global manufacturing, Chinese CNC machining parts factories have gone from being participants to game-changers. The orchestra of operations conducted in these factories is as impressive as it is critical to the world of manufacturing – all while singing the song of progress and precision.

Download this comprehensive ebook on CNC machining services around the globe.

- comparative analysis

- market players

- technology advancement

- challenges

- opportunities

And it is absolutely FREE!

A Comprehensive Look into Sourcing from a Chinese CNC Machining Parts Factory

An American purchasing manager named John Doe ventured into the largely untapped market of Asian manufacturers to source various plumbing products like faucets, shower heads, and drinking fountains.

- The Seek for Quality and Affordability

In search of a better deal, John made it his mission to find a balance between affordability and quality. His search led him to a promise in a Chinese CNC machining parts factory. With these factories, John saw the potential for savings he could bring back home.

- Touring a CNC Machining Parts Factory

On his first visit to a CNC machining parts factory in Shanghai, John was impressed by the high-tech processing equipment, which translates to precision and speed. Machining parts to perfection was a priority in these Chinese factories.

- Understanding the CNC Process

The CNC machining parts factory tends to favor materials like brass, stainless steel, and more, to intricately construct products like faucets and shower heads. This combination of technology and quality materials was a selling point for John.

- Balancing Demand with Supply

John anticipated that sourcing from a CNC machining parts factory would meet the high demand in America due to the quick turnaround time and ability to mass-produce excellent quality products.

Investing in a CNC Machining Parts Factory

John decided to invest in the CNC machining parts factory for the production of his goods. This daring move brought significant cost savings, flexibility, and exceptional quality.

Benefits of CNC Machining in the Shower Head and Faucet Industry

Manufacturers in this particular CNC machining parts factory specialized in making top-notch faucets and shower heads that would last a lifetime without losing their shine, thanks to the quality of materials used. John saw a vast market opportunity.

Ensuring Quality Control in a CNC Machine Parts Factory

Quality control is a major factor for any purchasing manager, and John was no exception. Regular audits were conducted in the CNC machining parts factory to ensure the quality of the goods was up to standard.

Future of Procurement in CNC Machining

John’s successful partnership with the CNC machining parts factory made a significant difference to his organization’s bottom line. He stood as an example to other international purchasing managers looking for quality and affordability.

Materials Commonly Used in the CNC Machining Parts Factories in China

| Material | Properties | Common Applications |

| Aluminum | High machinability, good conductivity, corrosion-resistant | Plumbing, electrical components, decorative parts |

| Brass | High machinability, good conductivity, corrosion-resistant | Plumbing, electrical components, decorative parts |

| Steel | Strong, durable, versatile | Construction, automotive, heavy machinery |

| Titanium | High strength-to-weight ratio, corrosion-resistant | Aerospace, medical devices, military applications |

| ABS Plastic | Cost-effective, impact-resistant, lightweight | Prototypes, consumer products, automotive interiors |

| Nylon | Wear-resistant, tough, flexible | Gears, bearings, structural components |

| Polycarbonate | Strong, impact-resistant, transparent | Optical lenses, medical devices, protective gear |

Conclusion

This real-life example of Tom sourcing from a Chinese CNC machining parts factory stands testament to the potential profitability and quality that can be obtained from China’s CNC factories. Thus, paving the way for a new business approach.

Reference

1. The Ultimate CNC Machining Guide

2. CNC Machining – A Complete Guide

3. CNC Machining: Types and Basic Components

4. CNC Machining Types: Different CNC Machines Used

5. CNC Machining Materials – Choosing the Right One for CNC Machining Project